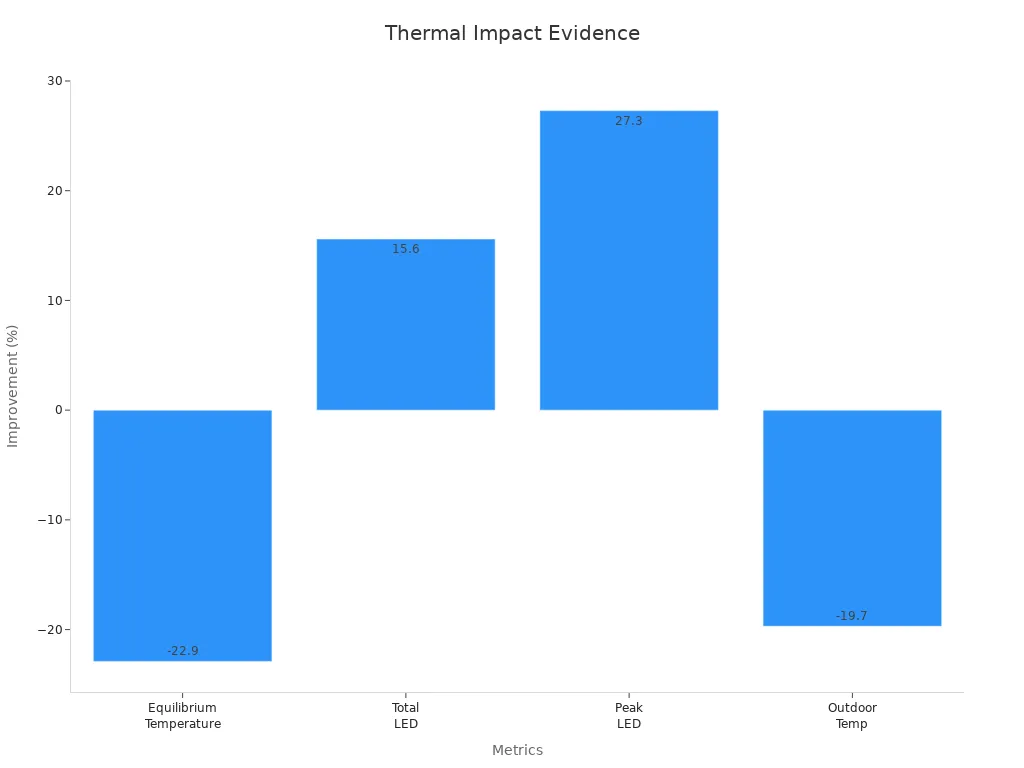

Proper thermal management plays a critical role in preventing overheating and device failure. Excess heat can shorten component lifespan and cause unexpected shutdowns. Devices such as smartphones, laptops, and battery-powered tools all depend on stable temperature control to maintain device performance. Research shows that effective thermal management lowers equilibrium temperature by nearly 23%, boosts LED emission intensity, and keeps outdoor devices cooler.

| Metric | Device with USRI | Control Device | Improvement (%) |

|---|---|---|---|

| Equilibrium Temperature (°C) | 43.7 | 56.7 | -22.9 |

| Total LED Emission Intensity | Baseline + 15.6% | Baseline | +15.6 |

| Outdoor Device Temperature (°C) | 33.8 | 42.1 | -19.7 |

Devices with advanced thermal management maintain steady temperature even under stress, leading to greater reliability and longer service life.

Electronic devices rely on precise control of temperature to function correctly. When heat builds up inside a device, sensitive components such as chips, batteries, and connectors face stress. Overheating can cause materials to expand and contract, leading to cracks or broken solder joints. This process, known as thermal cycling fatigue, often results in permanent damage.

Research shows that temperature is the leading cause of electronic device failures. The table below highlights the main causes:

| Cause of Failure | Percentage of Failures |

|---|---|

| Temperature | Over 55% |

| Vibration | About 45% |

| Humidity | 19% |

| Dust | 8% |

More than half of all failures in electronics come from poor thermal management. When devices operate above their recommended temperature range, chips can burn out and batteries degrade faster. These failures not only affect performance but also increase the risk of sudden shutdowns or permanent loss of function.

Tip: Keeping devices cool helps prevent costly repairs and extends their usable life.

Thermal management plays a key role in ensuring the performance and longevity of electronics. Devices that maintain optimal performance levels often use advanced cooling methods to keep internal temperatures stable. High temperatures speed up battery wear, reduce charging efficiency, and can even trigger dangerous events like thermal runaway in batteries.

Studies reveal several benefits of effective thermal management:

It prevents overheating, which can cause system failure and reduce device life.

It slows battery degradation, helping batteries last longer and perform better.

It improves charging efficiency and safety, especially in electric vehicles.

It uses techniques like conduction, convection, and both active and passive cooling to boost reliability.

Manufacturers design modern electronics with these strategies in mind. They use heat sinks, fans, and smart battery management systems to keep temperature under control. As a result, devices stay reliable and safe for longer periods. Good thermal management ensures that users experience fewer breakdowns and enjoy consistent performance throughout the device’s life.

Heat is a constant byproduct of electronic operation. Devices convert almost all electrical power into heat, which must be managed. When thermal challenges go unchecked, performance drops quickly. High temperatures cause molecular vibrations in materials, leading to expansion and stress. This stress can deform components and cause them to fail early. In data centers, operators measure heat output by tracking power input. If cooling systems cannot keep up, servers slow down or shut off to prevent damage. Studies show that electric vehicles lose up to 20% of their range when exposed to sustained high temperatures, such as 90°F. These thermal management challenges affect not only large systems but also everyday devices like laptops and smartphones. Users may notice slower speeds, unexpected shutdowns, or reduced battery life when devices overheat.

Poor thermal management can create serious safety risks. Overheating in lithium-ion batteries sometimes leads to thermal runaway, a rapid and uncontrollable rise in temperature. This process can cause fires, explosions, and the release of toxic gases. Case studies document incidents where batteries caught fire due to overcharging, physical damage, or exposure to excessive heat. The OVHcloud Strasbourg fire in March 2021 highlights the dangers in data centers. Overheating equipment and insufficient cooling contributed to the fire, which destroyed an entire building and caused major data loss. Electrical failures, faulty wiring, and poor maintenance often make these risks worse. Fire prevention systems and early detection are essential to protect both property and people.

Note: Proper storage, handling, and charging of batteries help prevent dangerous incidents. Data centers rely on strict safety protocols to reduce fire hazards.

Ignoring thermal challenges leads to expensive repairs and downtime. When devices overheat, components like chips, connectors, and batteries degrade faster. In data centers, a single overheating event can damage hundreds of servers, resulting in lost data and high replacement costs. The OVHcloud incident caused significant operational downtime and irreversible data loss for many businesses. For consumers, overheating can mean replacing a phone battery or even the entire device. Regular maintenance and effective cooling systems help avoid these costly outcomes. Addressing thermal management challenges early saves money and keeps devices running smoothly.

Every electronic device generates heat during operation. Heat management starts with understanding how heat moves from one place to another. Three main processes drive this movement: conduction, convection, and radiation. Conduction happens when heat travels through solid materials, such as from a processor to a heat sink. Convection moves heat away by using air or liquid, often with the help of fans or pumps. Radiation sends heat out as energy waves, but this plays a smaller role in most electronics.

Engineers use these principles to design cooling solutions that keep temperature under control. Good heat dissipation protects sensitive parts and improves energy efficiency. When devices stay cool, they work better and last longer. Temperature control also helps prevent sudden shutdowns and keeps performance steady.

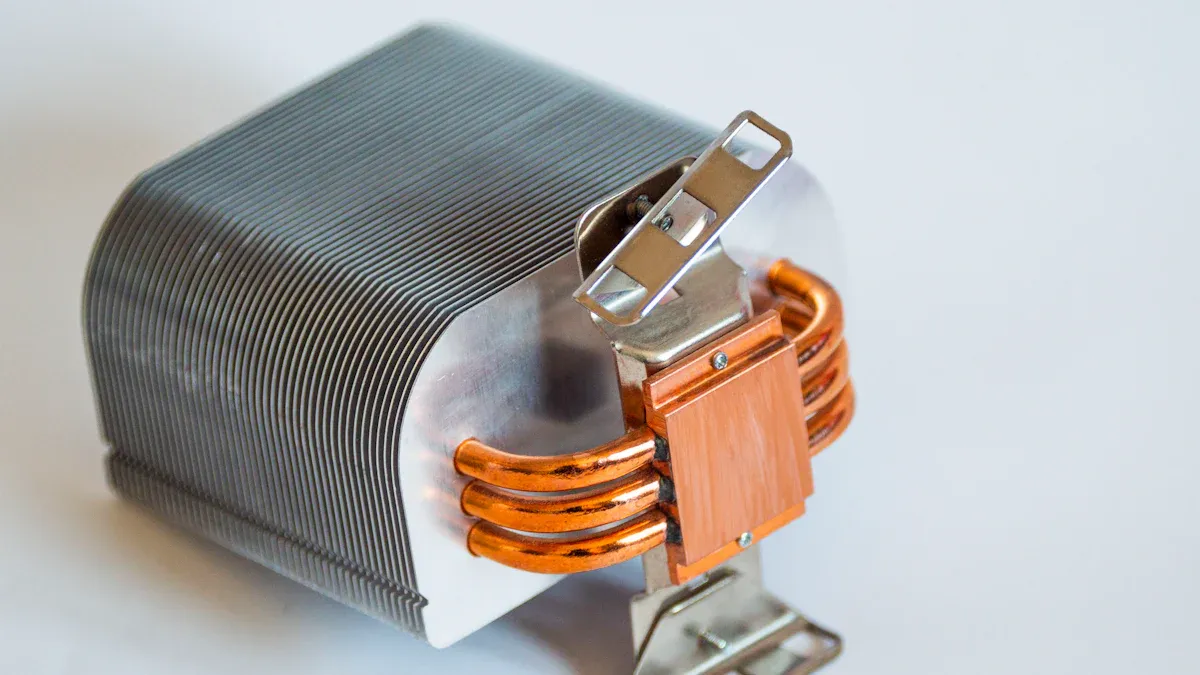

Thermal management applications use a range of cooling solutions to handle heat. Some devices rely on passive methods, such as heat sinks made from copper or aluminum. These materials pull heat away from hot components and spread it out. Other devices use active cooling methods, like fans or pumps, to move air or liquid and carry heat away faster.

The table below shows how different engineering principles support effective thermal management:

| Engineering Principle | Thermal Management Technique | Explanation and Effectiveness |

|---|---|---|

| Conduction | Heat sinks | Use materials with high thermal conductivity (e.g., copper, aluminum) and increased surface area (fins) to transfer heat rapidly from components to air. |

| Convection (free and forced) | Forced air cooling (fans) | Fans increase fluid velocity, enhancing heat transfer by maintaining a larger temperature gradient and replacing warmed air quickly. |

| Phase change and capillary action | Heat pipes | Utilize evaporation and condensation of a working fluid inside a sealed tube to transfer heat efficiently with minimal temperature difference. |

| Thermal interface materials | Thermal grease and interface pads | Improve thermal contact between components and heat sinks, reducing thermal resistance and enhancing heat flow. |

| Material science | Advanced materials (synthetic diamond, boron arsenide) | High thermal conductivity materials researched to improve cooling performance beyond traditional metals. |

| Computational fluid dynamics (CFD) | Thermal simulation | Enables prediction and optimization of temperature and airflow in designs, allowing early detection and correction of thermal issues. |

Many modern devices combine several cooling solutions for the best results. Good heat management not only improves energy efficiency but also extends device life. When engineers design systems with proper temperature control, electronics stay safe and reliable.

Tip: Regular cleaning of vents and fans helps maintain effective heat dissipation and prevents overheating.

Battery engineering has advanced rapidly to address the challenges of heat and safety in li-ion batteries. Battery management systems (BMS) play a central role in modern battery-powered devices. These systems use hardware components such as sensors to monitor temperature, voltage, and current. Advanced safety circuits prevent overcharging, over-discharging, and overheating. Communication devices allow the BMS to interact with other systems in electric vehicles and energy storage units.

Software in battery management systems controls hardware operation and performs real-time fault detection. Algorithms estimate the state of charge (SOC) and state of health (SOH) for each cell. BMS units balance cells, detect faults, and optimize charging and discharging. They help prevent hazardous conditions like short circuits and thermal runaway. Safe BMS design requires careful system architecture, sensor placement, and rigorous testing. These smart thermal management systems ensure battery safety, reliability, and longer service life.

Tip: A well-designed BMS can extend battery performance and reduce the risk of sudden failures.

Battery engineering focuses on preventing thermal runaway and improving battery performance. Research shows that mechanical abuse, internal short circuits, and overcharging can trigger dangerous heat buildup in li-ion batteries. Engineers use several methods to suppress these risks:

| Aspect | Description | Supporting References |

|---|---|---|

| Suppression Methods | Insulation, enhanced heat dissipation, flame retardant additives, epoxy resin plates between battery packs | Shahid et al. (2022), Hu et al. (2024) |

| Structural Design | Epoxy resin plates slow heat transfer and reduce damage from thermal runaway | Yang et al. (2023) |

| Safety Strategies | Heat insulation devices, current interrupting devices, safety vents, fire suppression | Sun et al. (2024), Wang et al. (2018) |

Thermal management systems, including liquid cooling and phase change materials, help maintain safe temperatures in li-ion batteries. These systems absorb and remove excess heat, preventing temperature spikes and reducing thermal stress. Uniform temperature control lowers the risk of thermal runaway and extends battery lifespan. Proper battery engineering and thermal management systems keep battery performance high and ensure safety in electric vehicles and portable devices.