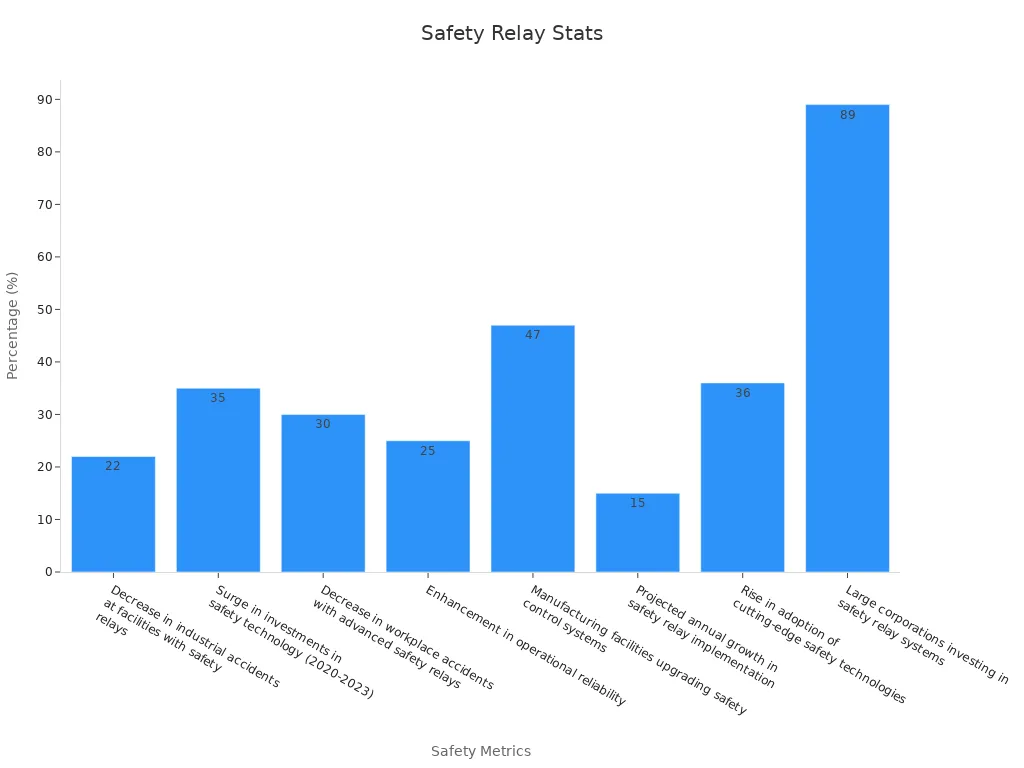

Neglecting safety relay upkeep exposes you to serious risks. Emergency repairs often cost up to ten times more than planned maintenance, and 70% of equipment failures are preventable. When you skip regular checks, you face costly downtime, lost profits, and even higher employee turnover. Reliable safety relays protect your workplace and boost operational reliability by 25%. The chart below shows how safety relay adoption leads to fewer accidents and greater safety across industries.

Regular maintenance of safety relay devices helps you avoid breakdowns, keep safety devices working, and ensure dependable safety systems.

You use safety relays to protect people and machines in industrial settings. These devices monitor and control safety functions, such as emergency stops and door interlocks. When a problem occurs, a safety relay reacts quickly to stop dangerous machinery. This fast response helps prevent injuries and equipment damage.

Industrial safety relays use an electromagnetic coil and a movable armature. When you apply power, the coil creates a magnetic field. This field moves the armature, which opens or closes contacts. Contacts can be Normally Open (NO) or Normally Closed (NC). This design ensures that safety relays work reliably in control systems.

Here is a table that shows the key features and performance metrics of safety relays:

| Aspect | Details |

|---|---|

| Relay Structure | Channels, contact types (NO, NC) |

| Principle of Operation | Electromagnetic coil and armature mechanism |

| Safety Features | Forcibly guided contacts, redundant design, monitoring functions |

| Electrical Parameters | Input/output voltage and current ratings, max switching capacity, contact resistance |

| Protection Features | Overload protection, DVDT capability |

| Diagnostic Coverage | Diagnostic coverage (DC) as per EN ISO 13849 standard |

| Environmental Factors | Ambient temperature, seismic and dust resistance, heat dissipation |

| Compliance Standards | EN ISO 13849, IEC 62061 |

| Example Specifications | Power supply: 24 V DC; Relay outputs: 3NO + 1NC; Max switching: 12 A; Contact resistance: <100 mΩ |

You must keep safety relays in good condition to ensure reliable operation. Over time, dust, heat, and vibration can affect how these devices work. If you ignore regular checks, the risk of failure increases. When a safety relay fails, safety devices may not work as expected. This can lead to accidents or machine damage.

Studies show that the reliability of safety relays drops as they age. Maintenance plays a big role in keeping them safe. When you perform timely inspections and repairs, you restore the relay’s ability to protect your workplace. Regular maintenance helps you spot problems early and fix them before they cause harm.

Tip: Schedule routine checks for all safety relays. Early action keeps your safety systems strong and dependable.

You should set up a regular inspection schedule for every safety relay in your facility. Start by checking each relay at least once every three months. Some high-use machines may need monthly checks. During each inspection, look for signs of wear, loose wiring, or discoloration. Use a checklist to make sure you do not miss any steps. Always follow the manufacturer's guidelines and your company’s safety standards. Regular monitoring helps you catch problems early and keeps your safety systems reliable.

Tip: Mark inspection dates on a visible calendar near your control panels. This helps everyone remember when the next check is due.

You must always check voltage and power before working on a safety relay. Never exceed the rated voltage for any relay. Turn off all power sources before you begin any work. Use only approved voltage testers and follow the correct procedures. The table below shows why careful voltage checks matter for safety and cost:

| Evidence Aspect | Details |

|---|---|

| Injury Statistics | - 18.3% of facilities had personal injury using handheld voltage testers over 5 years. - 11.7% experienced plant operation interruptions due to voltage testing incidents. - 2,210 nonfatal electrical injuries in 2017 (35% increase from 2016). - 60% of arc and burn incidents occurred at low voltages (<1,000 V), mostly on three-phase systems. - Estimated 20% reduction in electrical injuries possible by better absence-of-voltage verification. |

| Procedural Validation | - NFPA 70E-2015 Article 120.56 requires testing each phase conductor both phase-to-phase and phase-to-ground. - Test instruments must be verified on a known voltage source before and after testing. - Permanently mounted Absence-of-Voltage Testers (AVTs) like VeriSafe meet NFPA 70E-2018 Article 120.5 requirements. |

| Device Features Supporting Safety | - Automated voltage absence verification without exposure to hazardous voltages. - Tests phase-to-phase and phase-to-ground. - Built-in pre/post verification tests. - Rated Safety Integrity Level (SIL) 3 per IEC 61508. - Reduces reliance on PPE and human error. |

| Economic Impact | - Average direct cost of electrical injury: $50,000 to $80,000. - Indirect costs can be nearly four times direct costs. - 51% of injured workers missed over one week of work; 40% missed two weeks or more. |

| Training and Complexity | - Handheld testers require extensive training and PPE. - Complexity and time consumption can lead to procedural shortcuts and normalization of deviance. - Permanently mounted AVTs reduce complexity and risk of human error. |

You can reduce electrical injuries by 20% if you verify the absence of voltage before starting work. Always test your voltage tester on a known live source before and after use. This step proves your tester works and keeps you safe.

A clean environment helps your safety relay work better and last longer. Dust, moisture, and chemicals can cause serious problems. Here are some key points to remember:

Dust and conductive particles can get between relay contacts, causing failures or short circuits.

High temperature and humidity can lead to oxidation and condensation inside the relay, which damages contacts and insulation.

Corrosive gases, such as sulfuric or organic vapors, can form films on contacts and cause corrosion.

Water, chemicals, or oil can cause rust, resin breakdown, and even burns on relay surfaces.

Magnetic dust can stick to relay parts and lower performance.

You should keep your relay cabinets closed and use filters if needed. Clean the area around your safety relays often. Avoid placing relays near sources of heat, moisture, or chemicals. A controlled environment prevents malfunctions and extends the life of your safety relay.

You need to test each safety relay to make sure it works as designed. Use both manual and automated tests. Functional testing checks that the relay responds to input signals and changes state correctly. Many facilities use relays rated for Safety Integrity Level (SIL) 3, which means they have passed strict audits and tests. These tests include checking the mechanical linkage of force-guided contacts and monitoring logic circuits. Third-party organizations, such as TÜV, audit these procedures to meet IEC 61508 standards. When you use SIL-rated relays, you get higher reliability and safety. Manufacturers also take responsibility for safety calculations, which reduces your workload and risk.

Note: Always document your test results. This record helps you track relay performance and spot trends over time.

When you need to replace a safety relay, follow these steps to stay safe:

Turn off all power sources and lock out the circuit.

Use a voltage tester to confirm the absence of voltage.

Remove the old relay using insulated tools.

Check the wiring for damage or loose connections.

Install the new relay, making sure you match the wiring to the diagram.

Double-check all connections before restoring power.

Test the new relay to verify safe operation.

Never work on live circuits. Always avoid direct contact with exposed wires. Use proper wiring practices and follow all safety standards. Correct configuration and careful installation help prevent future problems.

⚠️ Always wear appropriate personal protective equipment (PPE) when working with electrical systems.

You will face several common faults when working with safety relays. Early detection helps you avoid downtime and keeps your safety systems strong. Regular inspection and testing let you spot problems before they cause harm.

The emergency stop button is a critical part of any safety relay system. If this button fails, machines may not stop when needed. You should check the wiring and contacts for wear or corrosion. Sometimes, dust or moisture can block the signal. Test the emergency stop button during every inspection. If you notice slow response or no action, replace the faulty parts right away.

Tip: Always label and test each emergency stop button so everyone knows it works.

Door interlocks prevent machines from running when guards or doors are open. Common faults include broken actuators, misaligned sensors, or loose wiring. You should inspect the sensing mechanisms and actuators for damage. Make sure the door closes fully and the interlock engages. If you find any misalignment or wear, fix it before restarting the machine.

Sensors and light curtains protect workers by stopping machines if someone enters a danger zone. Common faults here include dirty lenses, wiring issues, or failed sensors. Clean the sensors and check for loose connections. Test the system by breaking the light curtain beam to see if the safety relay responds. Replace any faulty sensors to keep your safety system reliable.