You want the best when it comes to wire splice connectors. In 2025, trusted brands like Amphenol, LEADSIGN, and TE Connectivity lead the way. Choosing the right brand matters for your safety and the long-term performance and reliability of your projects. In vehicles and heavy-duty settings, trusted brands offer strong locking, heat resistance, and waterproof features. Look for durability, easy installation, top certifications, and sustainability.

| Specification | Leading Brand Features |

|---|---|

| Current Rating | Up to 40 amps (Amphenol, TE Connectivity) |

| Sealing Protection | IP67 and IP6K9K with cover |

| Temperature Range | -40°C to +140°C |

| Application Areas | Trucks, buses, construction, automotive |

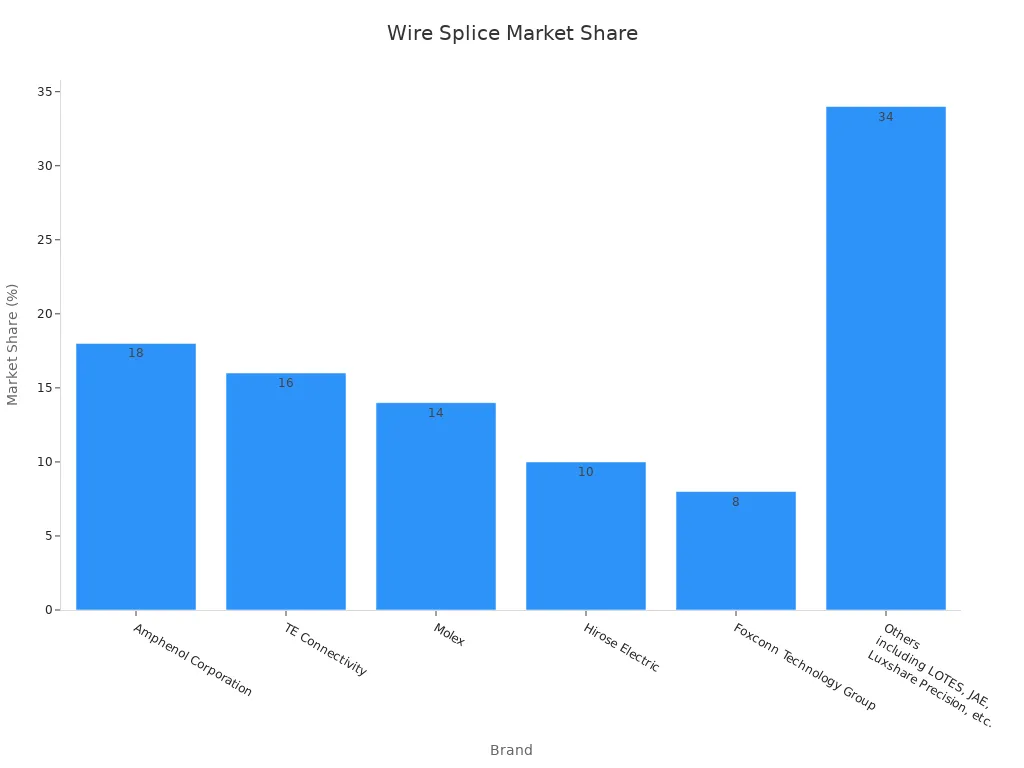

When you look for the best wire splice connectors, you want to know which brands lead the market. In 2025, Amphenol, TE Connectivity, and LEADSIGN stand out as trusted brands. These companies focus on performance, durability, and innovation. You also see IDEAL, EMC Fasteners, Molex, and Hirose Electric making a strong impact. Each brand brings something unique to the table.

| Brand | Market Share in 2025 (%) |

|---|---|

| Amphenol Corporation | 18 |

| TE Connectivity | 16 |

| Molex | 14 |

| Hirose Electric | 10 |

| Foxconn Technology Group | 8 |

| Others (including LOTES, JAE, Luxshare Precision, etc.) | 34 |

You see that Amphenol and TE Connectivity hold the largest shares. LEADSIGN, while newer, impresses with fast data speeds and compact designs. TE Connectivity and Amphenol both offer reliable, long-lasting connectors. Customer reviews praise these brands for their strong warranties and support. IDEAL and EMC Fasteners also deliver high-quality wire connectors for many uses.

You notice several trends shaping the connector market this year:

Automation, electric vehicles, and renewable energy drive demand for durable, eco-friendly connectors.

Safety and environmental standards like IEC, UL, and RoHS push brands to use better materials and safer designs.

Companies now use more environmentally friendly materials and processes.

Miniaturization and smart features become more common in new wire connectors.

Manufacturers invest in research and partnerships to meet strict regulations and create sustainable solutions.

Tip: When you choose wire splice connectors, look for IEC compliance and eco-friendly options. These features help ensure safety and future-proof your projects.

The North American market for IEC connectors over 250 V keeps growing. Strong safety codes in the US and Canada require reliable, sustainable connectors. You benefit from these changes because trusted brands now offer safer, greener, and more advanced products.

When you compare wire splice connectors, you want to look at several important features. Each brand offers different technical specifications. You can find connectors with dual row, micro, miniature, or single row designs. Pin counts range from less than 10 to more than 30. Rated voltage can be less than 10 volts or go above 100 volts. Some connectors handle less than 1 amp, while others support more than 10 amps.

You also need to check the mounting style. Some connectors use surface mount, through hole, or board-to-board methods. Material composition matters too. Brands use composite, metal like aluminum or stainless steel, and plastics such as nylon or polycarbonate. Insulation resistance can be less than 1 kΩ or greater than 10 kΩ. Operating temperature ranges from standard (−20 °C to 85 °C) to high (over 125 °C).

Contact plating options include gold, silver, or tin. Environmental compliance is key. Many connectors meet IEC standards, RoHS, and UL certification. Performance benchmarks show data rates above 10 Gbps, strong mechanical robustness, and high lifecycle reliability. You see these connectors used in aerospace, automotive, consumer electronics, and medical devices.

Industry forums like the IWCS 2025 Cable & Connectivity Industry Forum share technical research and benchmarking data. These events help you understand how brands invest in innovation and materials. You can use this information to make a detailed comparison of connectors for your project.

You want to know the strengths and weaknesses of each brand before you buy. Here is a table that summarizes what customer reviews and expert analysis say about some top brands:

| Brand | Pros | Cons |

|---|---|---|

| Wirenco | Custom wiring solutions, wide product range, trade program benefits, quality products, affordable pricing, fast delivery, expert advice | Low website traffic, anonymous payment methods, limited external reviews |

| CTC | Reliable and high-quality connectors, excellent customer service, industry-leading warranties, durable in harsh environments, flexible special orders, quick delivery, positive reputation | Limited product availability in some regions |

| Amphenol | Broad portfolio, strong innovation, high mechanical robustness, good for automotive and industrial use, meets strict certifications | Higher price point, complex installation for some models |

| TE Connectivity | Advanced materials, strong data rates, reliable in tough conditions, easy to install, good support | Some models have limited pin counts, premium pricing |

| Molex | Wide selection, good for consumer electronics, strong channel reach, cost-effective options | Not always suitable for high-heat or heavy-duty settings |